Choosing The Right Live Edge Wood For Your Epoxy River Tables

When it comes to live edge and epoxy river tables, the choice of wood is where everything begins. Every slab tells its own story — from colour and grain to rarity and texture. The right wood transforms a project from a simple tabletop into a statement piece. At Haig Designs, we work with a wide range of domestic and exotic woods to create epoxy furniture that feels alive, where the natural beauty of the grain meets the flowing clarity of resin.

Understanding The Beauty of Live Edge Wood

There are countless options when it comes to the types of wood used in live edge tables. Local favourites like walnut, maple, and oak remain classics for their strength, contrast, and warm tones. Then there are rarer species that push design boundaries — from black locust and elm to imported options like monkey pod, acacia, and padauk. Some of these slabs are sourced locally, others are imported from across the globe, with prices ranging from a few hundred to tens of thousands of dollars depending on rarity and figure. Whether it’s a rustic coffee table or a large epoxy river dining table, the type of wood you choose shapes the tone, character, and story of the piece.

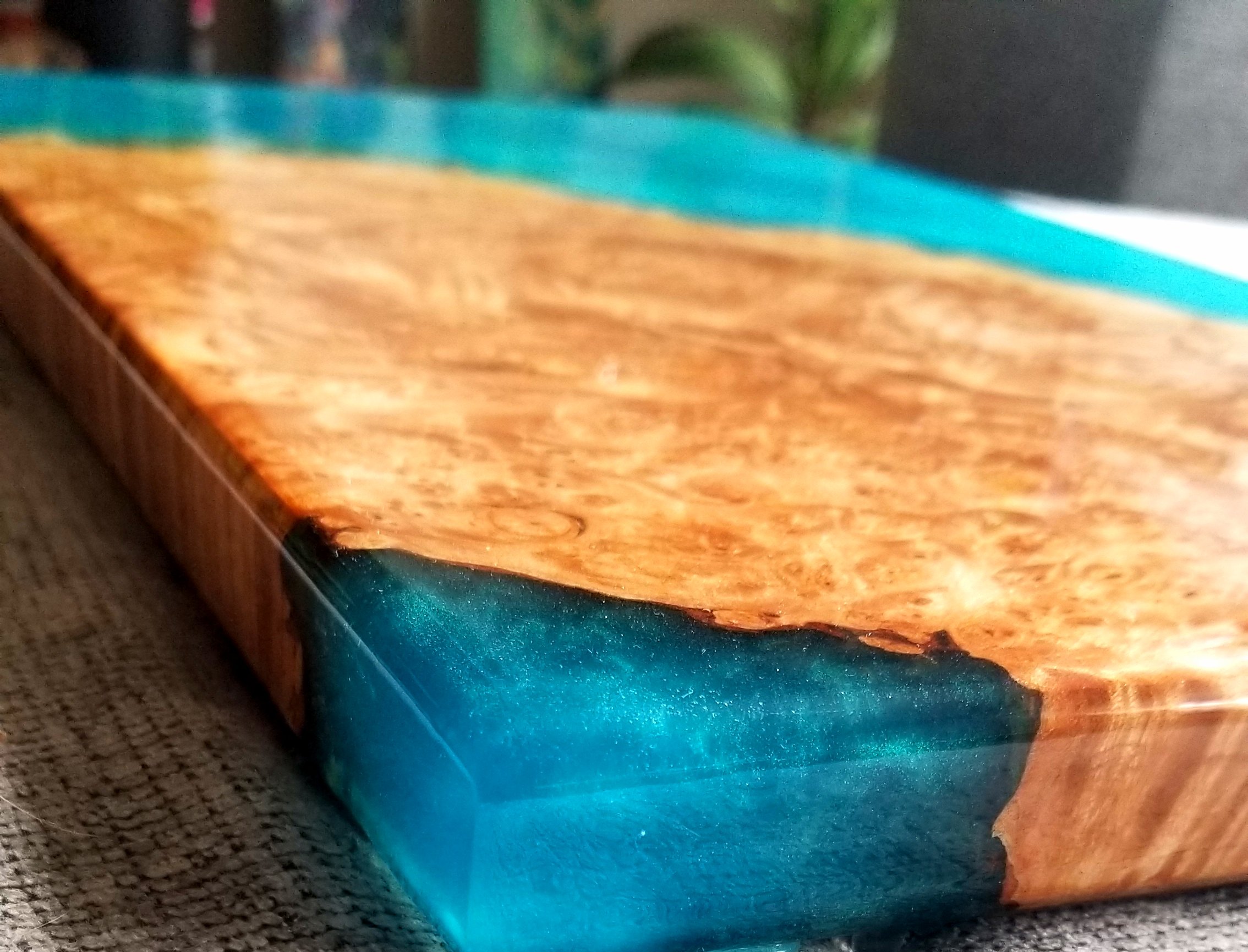

No two slabs of wood are ever the same, which is what makes live edge epoxy tables so captivating. The grain can be straight and clean or twist unpredictably like a river’s current. Some species feature subtle lines and neutral tones, while others showcase dramatic curls, shimmering chatoyance, or knots that tell decades of growth. The figure in the wood becomes even more pronounced once the resin is poured — it enhances contrast, adds depth, and gives a sense of movement beneath the glossy surface. At Haig Designs, we’re always chasing that perfect pairing of grain and epoxy resin, where colour and texture flow together naturally.

So how does the wood achieve these different grain patterns?

The grain and figure of wood are shaped by the tree’s life. Every stress, injury, or change in growth leaves a mark. A burl forms when a tree experiences some kind of stress or damage such as a fungus, virus, or physical wound. Instead of growing in a straight line, the grain begins to twist and swirl, forming intricate patterns that look almost fluid. This makes burl wood extremely sought-after in epoxy river tables because it offers movement and depth that can’t be replicated by ordinary cuts.

Then there’s spalted wood, another natural phenomenon that transforms an ordinary slab into something extraordinary. Spalting occurs when certain fungi begin to colonize dead or fallen wood. As they move through the fibers, they leave behind unique dark lines and zones of colour. Streaks of black, blue, brown, or even green that trace through the grain like lightning. While it might sound like decay, spalted wood that’s properly stabilized and kiln dried becomes one of the most visually striking materials used in resin art and epoxy furniture today. The fusion of spalted patterns under a clear pour of epoxy creates a striking blend of organic imperfection and polished design.

What Makes Burl Wood So Captivating?

Burl wood is where our obsession truly begins. We’re drawn to burl slabs for their wild, irregular grain and striking live edges. Formed from the unpredictable growth of a tree, burl wood delivers a texture that feels sculpted by nature itself. When used in epoxy river tables, the swirling grain interacts beautifully with clear or tinted resin, creating a visual rhythm that can resemble ocean waves, rolling clouds, or molten glass. Each burl table is entirely one of a kind, a blend of organic chaos and refined craftsmanship that continues to inspire every new project.

We’re constantly updating our inventory, hunting for those rare and beautifully shaped burls that bring our pieces to life. Working with burl can be more tedious than other woods, but the results are worth it. Burl slabs often contain small pockets of bark, air, or voids that need to be filled during sanding and finishing. These areas can be repaired using epoxy, and depending on the desired look, you can tint it with pigments, metallic powders, or even translucent dyes to create striking depth. Most makers source high-quality epoxy and pigments from reputable woodworking suppliers or resin specialty shops, ensuring that each repair blends seamlessly into the final piece. Some burl slabs feature deep voids or wide openings that must be fully filled with epoxy, creating dramatic contrasts between the natural wood and the crystal-clear resin. It’s a meticulous process, but one that transforms raw, irregular material into art you can feel and admire.

Kiln dried or air dried wood…does it really matter?

It does actually. When working with epoxy and live edge slabs, one thing is absolutely essential: the wood must be properly kiln dried. Kiln drying is the process of removing moisture from wood in a controlled environment, using heat and air circulation to bring it down to a stable level that prevents warping, cracking, and movement. For epoxy projects, moisture is the hidden culprit that can ruin a perfect pour. If the wood isn’t dry enough, it releases moisture into the resin, which can cause cloudy spots, bubbles, or even complete separation between the epoxy and the slab.

Most kiln-dried wood used for epoxy furniture should have a moisture content between 6% and 8%. Anything higher can cause problems down the line. The easiest way to check this is with a digital moisture meter, which can be purchased online or from most woodworking and hardware stores. These handheld devices read the internal moisture of your slab instantly, giving you peace of mind before you pour. Many makers test multiple spots across the surface and edges since moisture can vary throughout a single slab. Properly dried wood not only ensures a stable bond with epoxy but also prevents expansion and contraction as the seasons change — something air-dried or improperly stored slabs often struggle with.

Kiln drying also affects how the wood behaves once it’s been cut, sanded, and sealed. Because the process eliminates excess water, it allows finishes, sealers, and epoxy to bond evenly across the surface. The difference between a well-dried and a poorly dried slab often isn’t visible at first glance, but over time, it reveals itself in surface cracks, uneven epoxy edges, or movement that pulls the piece out of shape. Choosing kiln-dried wood is more than just a step in the process; it’s the foundation for stability, longevity, and a flawless final product.

Early in our career, we learned this lesson the hard way. We once purchased a slab that was labeled “kiln dried,” trusting the supplier’s word. At the time, we didn’t own a moisture meter, and everything seemed fine until the epoxy pour cured. Weeks later, the wood began to bow and pull away from the resin, leaving visible gaps along the edge. To save the piece, we had to install metal C-channels on the underside to reduce the movement and send the slab for proper kiln drying. Once stabilized, it looked as good as new, but it became a lasting reminder that preparation determines quality. Every mistake is a lesson in patience and precision, and this one taught us that even the most beautiful piece of wood means little if it isn’t ready to work with epoxy.

Now, before every project, we test and record moisture levels myself. It’s a simple step that prevents major headaches later and ensures every epoxy river table, live edge coffee table, or custom furniture piece we create will last for years to come.

Closing Thoughts

Every epoxy river table, live edge table, charcuterie board, and resin art piece at Haig Designs begins with a deep respect for the materials. Each slab is carefully hand-selected for its grain, colour, and natural edge, then paired with custom resin tones to create striking contrast and depth. Some pieces capture the movement of realistic ocean waves, while others preserve dried flowers within crystal-clear resin, transforming them into timeless custom wood and epoxy pieces. By blending wood and resin with precision and creativity, each design becomes a unique statement that highlights the beauty of nature and craftsmanship. The evolution of epoxy furniture has allowed woodworking to become more expressive than ever, turning slabs into enduring works of art that tell a story with every ripple, curl, and swirl in the grain.